For business owners in communities like Kennesaw, Marietta, and across the greater Atlanta area, a functioning commercial HVAC system isn't a luxury—it's the backbone of a productive and comfortable environment. Unexpected breakdowns can halt operations, impact employee morale, and deter customers, leading to costly downtime and emergency repairs. The key to avoiding these disruptions is a consistent, proactive maintenance strategy that addresses potential issues before they escalate into major failures.

This guide provides a comprehensive commercial HVAC maintenance checklist, breaking down the essential tasks that protect your investment, improve energy efficiency, and ensure year-round reliability. By following these steps, you can move from a reactive repair cycle to a strategic approach that saves money and secures your operational continuity. Beyond the specific tasks outlined here, understanding how to strategically plan and execute these checks is crucial. A well-organized plan prevents small problems from becoming large ones. You can learn more about mastering equipment maintenance scheduling to ensure maximum uptime for all your critical systems.

Let's explore the critical checks that Top Tech Mechanical performs to keep businesses in Woodstock, Roswell, and beyond running at peak performance, safeguarding both comfort and your bottom line.

1. Air Filter Inspection and Replacement

The first and most fundamental task on any commercial HVAC maintenance checklist is inspecting and replacing air filters. This simple step is your primary defense against system inefficiency, poor indoor air quality (IAQ), and premature equipment failure. Clogged filters restrict airflow, forcing the system's fan motor to work harder, consume more energy, and sustain unnecessary wear and tear.

Regular filter changes are crucial for maintaining a healthy and productive environment for employees, customers, and sensitive equipment. A clean filter effectively captures dust, pollen, debris, and other airborne contaminants, preventing them from circulating throughout your facility in areas like Marietta or Roswell and from accumulating on critical internal components like evaporator coils.

Why It's a Critical First Step

Ignoring air filters is one of the quickest ways to degrade system performance and drive up utility costs. The benefits of a consistent replacement schedule are immediate and substantial:

- Improved Energy Efficiency: Clean filters allow air to move freely, reducing the strain on the HVAC system and lowering energy consumption by up to 15%.

- Enhanced Indoor Air Quality: Proper filtration removes pollutants, leading to a healthier environment, which is especially critical in high-traffic commercial spaces or healthcare facilities.

- Extended Equipment Lifespan: By preventing dirt buildup on internal components, you reduce the risk of costly repairs and extend the operational life of your HVAC unit.

For businesses in Kennesaw, Acworth, and the surrounding areas, a proactive approach to filter maintenance is a key part of a comprehensive commercial HVAC maintenance strategy. For instance, a manufacturing facility near Cartersville might need monthly pre-filter changes due to high particulate loads, whereas a standard office building in Sandy Springs may follow a quarterly schedule using high-efficiency pleated filters.

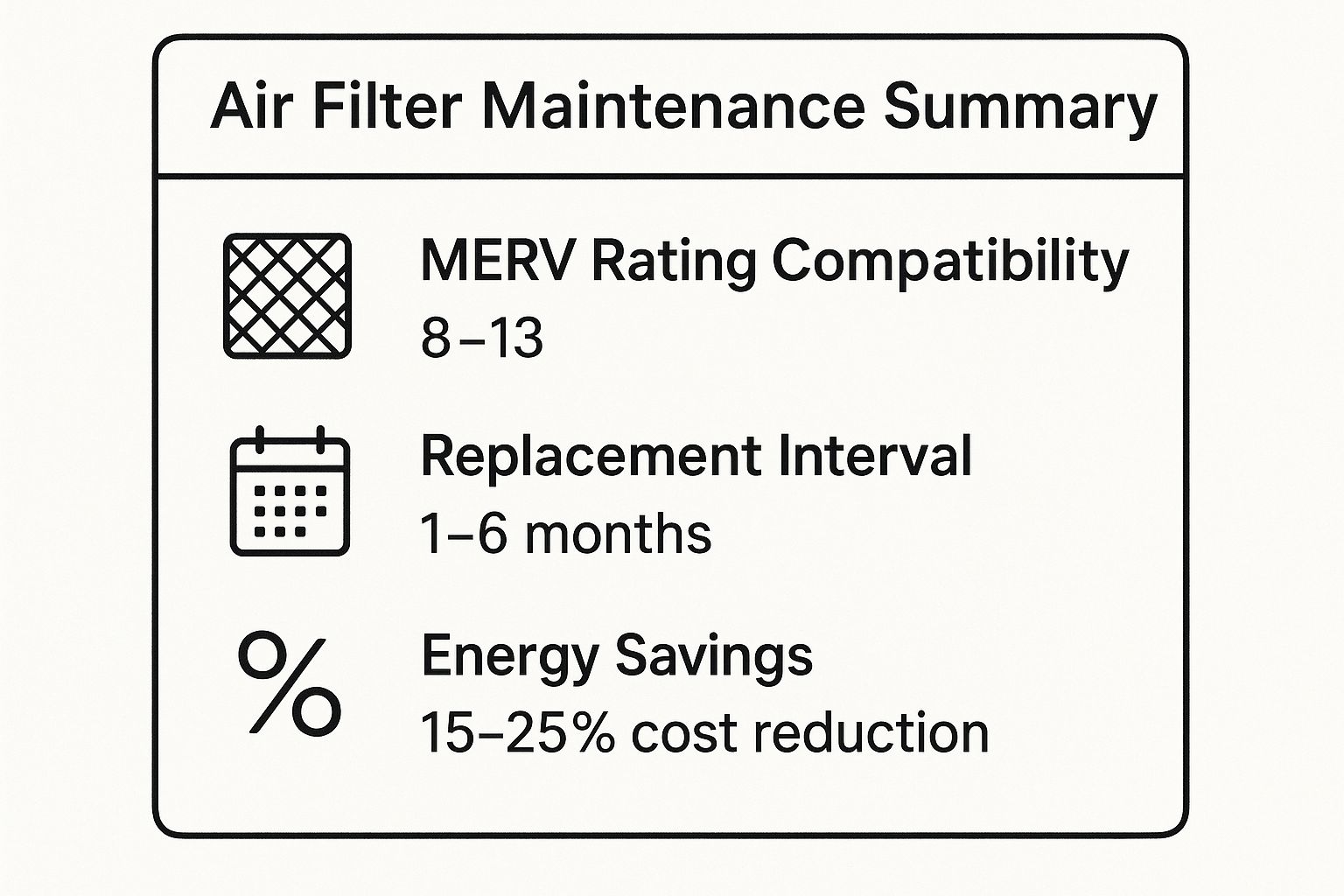

The following summary box provides a quick reference for key metrics in commercial air filter management.

As the data highlights, focusing on the correct filter type and replacement schedule can yield significant energy savings, making it a high-impact, low-cost maintenance task. At Top Tech Mechanical, we help businesses in Canton, Cumming, and across North Georgia select the right filters and establish a maintenance plan that fits their specific operational needs.

2. Thermostat and Control System Calibration

Following proper filtration, the next critical task on any commercial HVAC maintenance checklist is the calibration of thermostats and control systems. Your HVAC system is only as smart as the data it receives, and inaccurate temperature readings can lead to significant energy waste, occupant discomfort, and operational inefficiencies. This process involves systematically verifying and adjusting all temperature sensors, thermostats, and building automation system (BAS) controls to ensure they are operating precisely as intended.

Accurate calibration ensures the system responds correctly to the actual conditions within your facility. For businesses in areas like Atlanta or Smyrna, where temperature and humidity can fluctuate, precise control is key to managing operational costs and maintaining a comfortable environment for employees and clients. It prevents the system from running too long (overcooling or overheating) or cycling on and off unnecessarily, both of which cause excess wear on components.

Why It's a Critical Control Step

An uncalibrated control system works against your efficiency goals, often masking underlying performance issues. The benefits of regular calibration are directly tied to operational precision and cost management:

- Optimized Energy Consumption: When thermostats and sensors read temperatures correctly, the HVAC system runs only when needed, preventing energy waste and lowering utility bills.

- Consistent Occupant Comfort: Accurate temperature management eliminates hot and cold spots, creating a more stable and comfortable indoor environment for everyone.

- Improved System Diagnostics: Calibration provides a reliable baseline, making it easier for technicians to diagnose other potential issues within the HVAC system accurately.

Precision is paramount in many commercial settings. For example, a data center in Kennesaw might require setpoints accurate to within ±2°F to protect sensitive servers, while a hospital operating room in Marietta demands an even tighter tolerance of ±1°F for patient safety. Even a retail space in Woodstock benefits from precise zone-specific temperature controls to enhance customer comfort and manage energy use across different areas. For a deeper understanding of how these zones are managed, you can learn more about zone control systems on dev.toptechmech.com.

At Top Tech Mechanical, our technicians use calibrated reference thermometers to verify sensor accuracy, test control sequences, and ensure all scheduling functions, like night setbacks, are working correctly, providing businesses in Powder Springs and beyond with the precision control they need.

3. Coil Cleaning and Inspection

A crucial task in any comprehensive commercial HVAC maintenance checklist is the thorough cleaning and inspection of evaporator and condenser coils. These coils are the heart of your system's heat exchange process, and when they become coated with dirt, dust, grease, or biological growth, their ability to transfer heat is severely compromised. This forces the entire system to run longer and harder, dramatically increasing energy consumption and a-ccelerating component wear.

Proper coil maintenance involves more than a quick rinse; it requires a detailed examination to identify the type of buildup and select the appropriate cleaning method. For businesses in areas from Kennesaw to Vinings, keeping coils clean ensures optimal performance, extends equipment life, and supports better indoor air quality. A clean coil not only cools or heats more effectively but also prevents contaminants from entering your building's air supply.

Why It's a Critical Step

Neglecting coil cleaning directly translates to higher operational costs and a greater likelihood of system failure. The dirt acts as an insulator, preventing efficient heat transfer and causing issues that ripple through the entire HVAC system.

- Restored Energy Efficiency: Clean coils can improve system efficiency by up to 30%, leading to significant reductions in monthly utility bills.

- Improved System Performance: A clean system can achieve desired temperatures faster and maintain them more consistently, improving comfort for occupants.

- Prevention of Costly Repairs: Overworked compressors and fan motors due to dirty coils are a leading cause of premature equipment failure. Regular cleaning mitigates this risk.

The required frequency of coil cleaning varies by environment. For instance, a restaurant in bustling Marietta or Smyrna may need monthly cleaning to combat grease buildup, while a manufacturing plant in Cartersville might require quarterly service due to industrial particulates. At Top Tech Mechanical, we develop customized coil maintenance plans that address the unique challenges of your commercial facility, whether you're in Ball Ground or East Cobb.

4. Belt and Pulley System Maintenance

A crucial but often overlooked item on any commercial HVAC maintenance checklist is the inspection and servicing of belt and pulley systems. These components are the workhorses that transfer power from motors to critical equipment like fans and compressors in many commercial units. A worn, misaligned, or improperly tensioned belt can lead to significant energy waste, operational noise, and abrupt system failures.

Proper maintenance ensures that this power transmission is smooth and efficient, preventing the premature breakdown of expensive motors and fan assemblies. For facilities with large air handlers, such as office buildings in Atlanta or industrial exhaust systems in Cartersville, belt-driven components are central to system operation. Neglecting them directly impacts airflow, system performance, and component longevity.

Why It's a Critical System Check

Ignoring belt and pulley health is a direct path to unexpected downtime and costly emergency repairs. Consistent, professional attention to these mechanical components provides immediate and long-term advantages:

- Prevents Unplanned Downtime: A snapped belt can bring your entire HVAC system to a halt, disrupting business operations. Regular inspections identify wear and tear before it leads to failure.

- Boosts Energy Efficiency: Slipping belts waste energy by failing to transfer full power from the motor, forcing the system to work harder to achieve the desired airflow and temperature.

- Extends Equipment Life: Proper tension and alignment reduce stress on motor bearings and fan shafts, significantly extending the lifespan of these vital and expensive components.

For businesses in Kennesaw, Marietta, and Woodstock, ensuring these mechanical systems are in top condition is essential for reliable HVAC performance year-round. For example, a retail space in a Roswell shopping center relies on its rooftop unit's belt-driven fans to maintain customer comfort, making proactive belt replacement a smart investment.

As the video demonstrates, proper tensioning is a precise task that prevents both slippage and excessive strain. Including belt and pulley checks in a scheduled service plan ensures these tasks are handled correctly. You can learn more about how a comprehensive maintenance plan saves you more than you think. At Top Tech Mechanical, our technicians ensure every component, down to the last belt, is optimized for peak performance.

5. Refrigerant Level and Leak Detection

Systematic monitoring of refrigerant levels and the proactive detection of leaks are essential components of any comprehensive commercial HVAC maintenance checklist. Refrigerant is the lifeblood of your cooling system, and incorrect levels can drastically reduce efficiency, cause component failure, and lead to costly repairs. Low refrigerant is almost always a sign of a leak, which not only harms your system but also poses an environmental risk.

Ensuring the correct refrigerant charge allows the system to achieve its designed cooling capacity and efficiency. Technicians use specialized tools like pressure gauges and electronic leak detectors to verify levels and pinpoint even the smallest leaks. Addressing these issues promptly is critical for maintaining optimal performance and complying with strict EPA regulations regarding refrigerant handling and release.

Why It's a Critical Step

An incorrect refrigerant charge forces your entire system to work harder, leading to higher energy bills and accelerated wear on critical parts like the compressor. For businesses in areas like Woodstock or Johns Creek, where cooling demands are high, this can significantly impact operational costs.

- Optimal Cooling Performance: A correctly charged system delivers consistent and reliable cooling, which is vital for environments like data centers or hospital operating rooms.

- Energy Savings: Systems with the right refrigerant levels operate at peak efficiency, preventing the spike in energy consumption associated with an undercharged or overcharged unit.

- Regulatory Compliance: Proper leak detection, repair, and documentation ensure your business complies with EPA Section 608 regulations, avoiding potential fines.

- Prevents Major Failures: Catching and repairing small leaks prevents catastrophic compressor failure, one of the most expensive HVAC repairs.

For instance, a supermarket in Smyrna relies on precise refrigerant charges for its refrigeration cases, while an office building in Milton needs optimal levels for employee comfort. Regular checks are a non-negotiable part of responsible system ownership.

At Top Tech Mechanical, our EPA-certified technicians are experts in refrigerant management. We perform meticulous leak detection and recharging services for businesses across the Kennesaw area, ensuring your system runs efficiently and reliably.

6. Electrical Connection and Component Testing

A thorough inspection of electrical connections and components is a non-negotiable part of any comprehensive commercial HVAC maintenance checklist. Over time, vibrations, thermal cycling, and environmental factors can cause electrical terminals to loosen, corrode, or degrade. These seemingly minor issues can lead to major system failures, create significant fire hazards, and result in catastrophic equipment damage.

This critical step involves a detailed examination of all electrical elements, including wiring, contactors, relays, capacitors, and safety controls. Technicians perform voltage and amperage tests, verifying that all components are operating within the manufacturer's specified ranges. Tightening every connection ensures a secure and efficient flow of electricity, which is fundamental to the safe and reliable operation of the entire HVAC system.

Why It's a Critical Step

Loose or faulty electrical connections are a leading cause of HVAC system breakdowns and are among the most dangerous. Proactively testing and servicing these components prevents unexpected downtime and ensures the safety of your property and occupants.

- Prevents Catastrophic Failure: A loose connection can cause arcing, which generates intense heat, melting wires and destroying sensitive components like compressors and motors.

- Enhances Safety: Identifying and correcting electrical hazards like frayed wiring or failing safety circuits is essential to prevent electrical shocks and fires.

- Improves System Reliability: Ensuring that contactors and relays function correctly guarantees that the system starts, runs, and stops as intended, preventing unnecessary strain and wear.

This process is vital across all commercial settings. For example, a manufacturing facility in Cartersville with high-amperage motors relies on secure connections to prevent production-halting failures, while a hospital in Marietta requires flawless electrical integrity for its critical HVAC systems. In every business from Kennesaw to Sandy Springs, annual electrical maintenance is a cornerstone of a robust HVAC care strategy. At Top Tech Mechanical, our technicians follow strict lockout/tagout procedures to perform these checks safely and document all readings to monitor trends and predict potential failures.

7. Lubrication of Motors and Moving Parts

Proper lubrication of moving components is the lifeblood of a commercial HVAC system, ensuring all mechanical parts operate smoothly and efficiently. This critical task involves the systematic application of manufacturer-specified lubricants to motors, bearings, fan shafts, and other moving components. Correct lubrication reduces friction, which is a primary cause of heat generation, component wear, and eventual equipment failure.

Without adequate lubrication, metal-on-metal contact creates excessive stress and heat, leading to premature breakdown and costly emergency repairs. For businesses in high-demand environments like manufacturing facilities in Cartersville or large retail centers in Woodstock, maintaining a strict lubrication schedule is essential for operational continuity. This step prevents the silent but steady degradation of your system's core mechanical parts.

Why It's a Critical Maintenance Step

Neglecting lubrication guarantees increased operational costs and a shortened equipment lifespan. The benefits of a well-documented lubrication program are vital for any commercial HVAC maintenance checklist:

- Reduced Friction and Wear: Proper lubrication creates a thin film between moving surfaces, significantly minimizing friction and preventing the wear and tear that leads to component failure.

- Lower Energy Consumption: By reducing friction, motors and fans can operate with less resistance. This directly translates to lower energy usage and reduced utility bills for your facility.

- Prevents Overheating: Lubricants help dissipate heat generated by moving parts. This prevents motors and bearings from overheating, which can cause catastrophic system failure and safety hazards.

A proactive approach to this task is non-negotiable. For example, a large office building in Sandy Springs or Kennesaw might require quarterly lubrication of its rooftop units' fan motors, while a food processing plant near Dallas would need to use specialized, food-grade lubricants on a more frequent schedule to meet health and safety standards. Always clean grease fittings before applying new lubricant to avoid contamination and keep detailed logs of when and how much lubricant was used.

At Top Tech Mechanical, our technicians ensure every moving part receives the correct type and amount of lubricant according to OEM specifications, safeguarding your investment and keeping your system running reliably.

8. Drain Pan and Condensate System Maintenance

An often-overlooked yet critical part of any commercial HVAC maintenance checklist is the inspection and cleaning of the condensate system. As your HVAC unit cools the air, it removes moisture that collects in a drain pan and is channeled away via a drain line. A blockage or failure in this system can lead to water overflow, causing significant property damage, microbial growth, and potential system shutdowns.

Regular maintenance ensures this system functions correctly, protecting your building's interior and maintaining a healthy environment. This process involves thoroughly cleaning the drain pan, clearing any obstructions from the condensate line, and testing components like condensate pumps and float switches to guarantee proper operation, especially for businesses in humid climates like those found in Marietta or Smyrna.

Why It's a Critical Step

Neglecting the condensate system is a direct path to costly water damage and unhealthy indoor air. Proper maintenance prevents clogs from dirt, algae, and sludge buildup, which can cause water to back up and spill into ceilings, walls, or onto sensitive equipment.

- Prevents Water Damage: A clear and functional drain system is your best defense against overflows that can ruin drywall, flooring, and inventory, leading to expensive repairs and operational downtime.

- Improves Indoor Air Quality: Stagnant water in a clogged drain pan is an ideal breeding ground for mold, mildew, and bacteria. Keeping it clean prevents these contaminants from entering your facility's air supply.

- Ensures System Reliability: A system shutdown due to a failed condensate pump or a tripped overflow switch can halt business operations. Proactive checks ensure the entire system remains reliable.

For instance, a busy restaurant kitchen in Kennesaw produces high levels of moisture and grease, requiring frequent drain line cleaning to prevent blockages. Similarly, a healthcare facility in Woodstock cannot risk microbial growth, making regular drain pan sanitation and testing of pump alarms an absolute necessity.

The following summary box provides a quick reference for key tasks in condensate system management.

As the data illustrates, simple, preventative tasks like verifying drain slope and using enzyme-based cleaners can prevent major system failures and health hazards. At Top Tech Mechanical, our comprehensive maintenance plans include detailed condensate system checks to protect your commercial property in communities like Dallas and Hiram and ensure uninterrupted performance.

8-Point Commercial HVAC Maintenance Checklist Comparison

| Maintenance Task | Implementation Complexity 🔄 | Resource Requirements ⚡ | Expected Outcomes 📊 | Ideal Use Cases 💡 | Key Advantages ⭐ |

|---|---|---|---|---|---|

| Air Filter Inspection and Replacement | Moderate – requires regular checks ✅ | Moderate – filters, labor, pressure gauges | Improved air quality, energy savings (15-25%), extended equipment life | Hospitals, manufacturing, offices with air quality focus | Enhances indoor health, prevents system damage, reduces costs |

| Thermostat and Control System Calibration | High – needs trained techs, BAS integration | Moderate – calibration tools, software access | Consistent comfort, energy waste reduction, precise zone control | Critical environments like hospitals, data centers, retail | Precise temperature control, energy management data |

| Coil Cleaning and Inspection | Moderate to High – labor-intensive, shutdown needed | Moderate – cleaning chemicals, tools, PPE | Restored heat transfer, energy savings (10-30%), extended coil life | Kitchens, coastal buildings, industrial facilities | Improves efficiency, prevents corrosion, reduces mold |

| Belt and Pulley System Maintenance | Moderate – requires technical skill and safety measures | Low to Moderate – belts, tools, alignment devices | Prevents shutdowns, maintains equipment performance, energy saving | Large commercial buildings, industrial plants | Avoids failures, reduces energy waste, extends equipment life |

| Refrigerant Level and Leak Detection | High – certified technicians required | High – leak detectors, recovery equipment | Maintains cooling efficiency, EPA compliance, environmental protection | Supermarkets, data centers, hospitals | Prevents compressor damage, ensures regulation compliance |

| Electrical Connection and Component Testing | High – needs qualified electricians and safety protocols | Moderate to High – specialized test equipment | Prevents fires, reduces downtime, detects faults early | Critical care, manufacturing, commercial kitchens | Ensures safety, reliability, and equipment longevity |

| Lubrication of Motors and Moving Parts | Low to Moderate – routine but requires accuracy | Low to Moderate – lubricants, automated systems | Extended bearing/motor life, reduced energy use, quiet operation | Manufacturing, large buildings, food processing | Prevents wear, reduces replacements, maintains smooth operation |

| Drain Pan and Condensate System Maintenance | Low to Moderate – regular cleaning, some chemical use | Low – cleaning supplies, testing tools | Prevents water damage, microbial growth, system overflows | Hospitals, restaurants, humid climates | Protects structures, improves air quality, prevents shutdowns |

Partner with Top Tech Mechanical for Ultimate Peace of Mind

Navigating the intricacies of a comprehensive commercial HVAC maintenance checklist reveals a fundamental truth: proactive care is not just a recommendation, it's a strategic necessity. From ensuring consistent air filter replacement and calibrating sensitive thermostat controls to inspecting electrical connections and maintaining condensate systems, each task is a critical piece of a larger operational puzzle. Mastering these steps is the key to unlocking significant long-term value, transforming your HVAC system from a potential liability into a reliable, high-performing asset for your business.

The benefits extend far beyond simple comfort. A meticulously maintained system directly impacts your bottom line through improved energy efficiency, which lowers utility bills month after month. It also prevents the vast majority of unexpected, costly breakdowns that can disrupt operations, damage inventory, and create an uncomfortable environment for both employees and customers. Ultimately, consistent maintenance is an investment in business continuity, occupant well-being, and financial predictability.

Turning Knowledge into Action with a Trusted Partner

While understanding this checklist empowers property managers and business owners, the execution demands the precision and expertise of certified professionals. The complexities of refrigerant handling, electrical component testing, and mechanical system lubrication require specialized tools and deep diagnostic experience. This is where partnering with a dedicated expert becomes invaluable.

For businesses throughout the metro Atlanta area, from Kennesaw and Marietta to Roswell and Dunwoody, Top Tech Mechanical provides the expert support needed to translate this checklist into a seamless, effective maintenance strategy. Our technicians specialize in commercial services, including commercial rooftop AC repair, commercial AC installation, and customized commercial HVAC maintenance plans tailored to your facility's unique demands. We don't just fix problems; we prevent them.

While Top Tech Mechanical handles the technical aspects of your system's health, consider how operational support can further enhance reliability. For instance, a dedicated HVAC answering service can ensure that even after-hours emergency calls are professionally managed and dispatched, providing an additional layer of protection and responsiveness for your business. This integrated approach, combining expert fieldwork with streamlined communication, creates a truly resilient operational framework. By entrusting your system to a team that lives and breathes these protocols, you can focus on running your business with the complete peace of mind that your environment is protected.

Ready to take the guesswork out of your system's upkeep? Let the certified experts at Top Tech Mechanical implement a proactive commercial HVAC maintenance checklist designed specifically for your facility. Visit us online at Top Tech Mechanical to schedule a consultation and protect your investment today.